Celebrating 65 years of Ayoubi Steel!

Advantages and Disadvantages of Conventional Pallet Racking

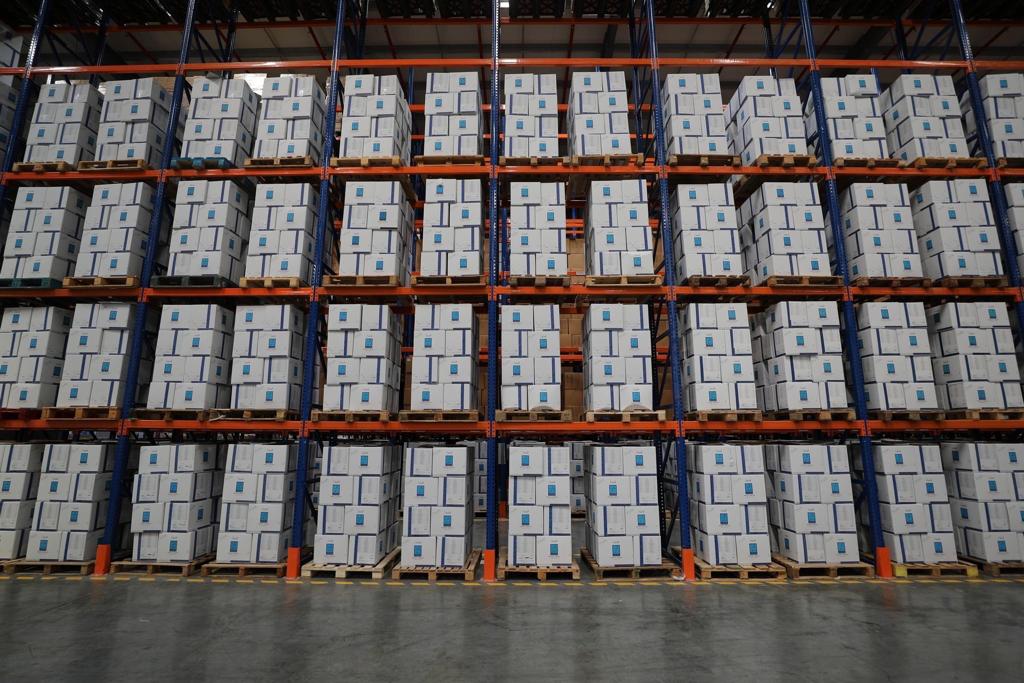

The conventional pallet racking which is also known as the “selective” pallet racking is the most popular configuration among warehouses. Its popularity is due to its versatility in keeping a wide range of merchandise on different types of pallets. It allows for 100% access to each load and can store items at various heights. A wire mesh can also be utilized to protect items from falling or damage.

This system is extremely cost effective, not only because of the racking itself, but also because there it eliminates the use of expensive handling equipment as well as specialized building requirements and supervision.

This system is suitable for warehouses where it is necessary to store a range of articles in all types of pallets, thus it is the most commonly used system for storage of palletized loads. It is suitable for handling combined storage/order picking areas since it provides 100% direct and immediate access to all goods and articles.

This system consists of bolted vertical frames and hooked horizontal beams, the choice of the beam section depends on the load and the type of pallet used and the size of the cell. In the event that there are no pallets or the pallets are small or heavy, then a conventional pallet racking system with an L-section beam is used.

Advantages of Conventional Pallet Racking

- 100% access to all pallets

- Can be configured in various ways depending on your requirements

- Easy to install and dismantle

- Modular structure with the ability to expand vertically and horizontally for future needs

Disadvantages of Conventional Pallet Racking

- Lower storage density compared to other types of racking

- Less efficient use of space since aisle space is not fully optimized

For inquiries and to request a free quotation, please visit the contact us form page by clicking on the below button: